White Space Consulting

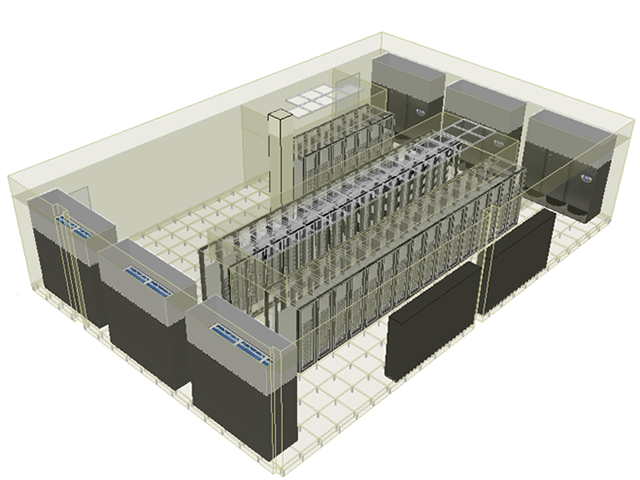

The company provides a multi-discipline consulting engineering service for technical advice, reporting, design and project oversight. DFL are able to offer this service to clients in most parts of the UK, Europe, Russia, UAE and Far East. We have built up a wide base of expertise and experience and are happy to engage with clients to resolve difficult power and cooling issues and provide practical and achievable end results.