Modelling Sets

DFL offers modelling sets to suit the variables of client new build stress testing, technical validation and performance studies. We offer a full suite of CFD simulation and analysis of cooling performance, integrated system testing using either CFD or stand-alone models and scale modelling for presentation and project clarity. For new builds as well as existing installations, where the issues of air flow management and cooling delivery to racks is critical, a full suite of CFD modelling can be built from a blank page to produce a thorough understanding of the cooling envelope before it is constructed. Modelling for either retrospective or new build integrated system testing is fundamental to the work we do for clients who wish to stress test their IT environments and ensure functional validation in a variety of load conditions and failure scenarios. As part of the presentation process for complicated projects and where different audiences are shown new concepts, we offer detailed scale model construction. We will take on this work as part of a construction project or as stand-alone instruction to assist a client in gaining a full understanding of how the proposed solution is assembled.

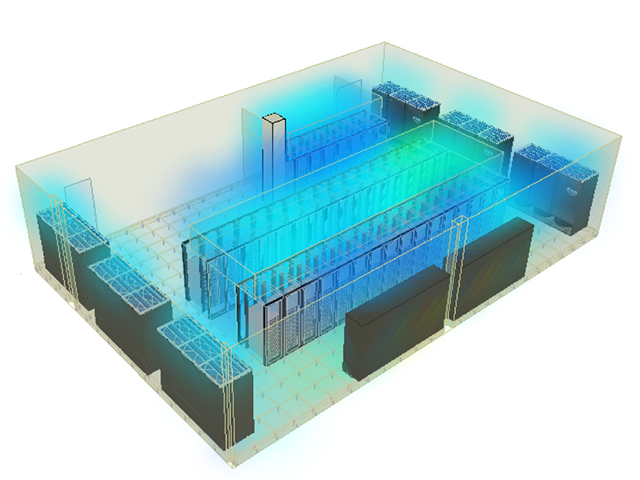

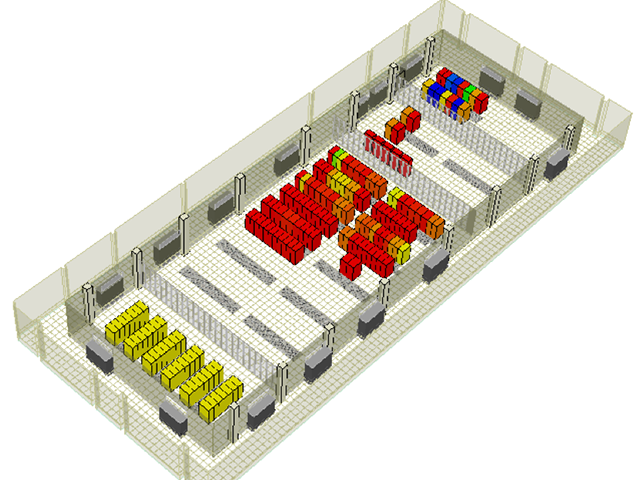

Computational Fluid Dynamics

For specific projects, and where there is a need to predict and simulate the conditions within a new or proposed space, we will undertake a full CFD build. This work will include the gathering of all base construction data, fully specifying and collating rack layouts, positioning of hardware, hardware bills of materials, heat output data, equipment air transfer rates, hardware modelling and creation. Models may include underfloor and above rack services, hot and cold aisle arrangements, cooling unit locations, air flow variation and underfloor pressurisation values. Simulations may include any permutation of cooling load to create different conditions and provide the client with an in depth cross-section of what the built end-product will look like and how it will perform.